Integral Concrete Colour

During manufacturing the GRC mixture can be coloured by blending mineral oxide pigments with either grey or white cement.

Our products are available in four standard colours: Charcoal, Concrete Grey, White and Kalgoorlie.

Please note: To ensure you are receiving the ‘true’ colour, we recommend requesting colour sample tiles from us before committing to a colour. Images on the website are a good reference point but are by no means indicative of true colours.

Also note that we don’t recommend the use of dark mineral oxides, like Charcoal, for outdoor seating. Dark surfaces can reach high temperatures when placed in full sun.

Charcoal

Made by adding coloured mineral oxide during manufacture

Concrete Grey

Made using general-purpose (GP) cement

White

Made with pure white cement

Kalgoorlie

Made by adding coloured mineral oxide during manufacture

Custom Concrete Colours

Other mineral oxide colours are available on special request — refer to the CCS Colour Card.

*Sample colour tiles available on request, simply mention to our sales team during initial correspondence.

Painted Colour, Special Effects & Finishes

Glassfibre Reinforced Concrete (GRC) lends itself to custom design and innovation, it can easily be moulded to reproduce shapes, reliefs and patterns to compliment any design theme.

Our products can also be integrally coloured with mineral oxide pigments or painted to match virtually any colour.

Painted Colour

Our products can be painted to achieve virtually any colour, including two-tone, patterned and textured paint finishes. Typically we use high-quality exterior, low sheen, water-based acrylic paints to achieve your desired colour. Complimentary black Bitumen-based waterproofing is included.

Choose the colour you want, let us know the name and code and we’ll purchase the paints and apply it to your order.

Please note that we do not recommend painting seating units without timber tops or the use of dark colours for outdoor seating. Dark surfaces can reach high temperatures when placed in full sun.

Specialty Paints

We use specialised paints to achieve rust, copper and aged copper. Bridge paint (micaceous iron oxide paint) can also be applied to our products.

Choose the colour you want, let us know the name and code and we’ll purchase the paints and apply it to your order.

Please note that we do not recommend painting seating units without a timber deck cover.

Pitted Surface

Some of our products can be manufactured with a pitted surface.

Additives are applied to the mould surface prior to spraying the GRC mixture into the mould. This creates a dimpled and pitted effect on the exterior product surface.

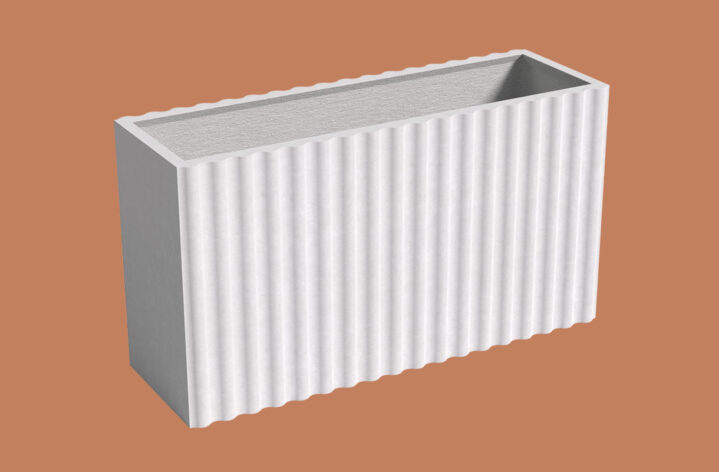

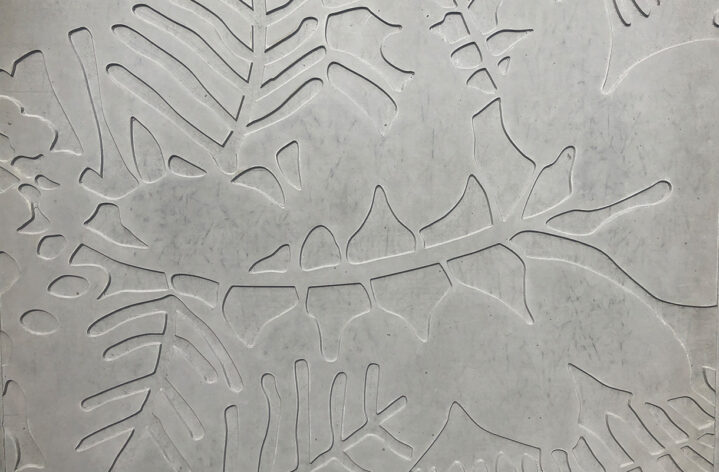

Patterned Surface

Should you need a special design or pattern moulded onto the product surface of a square or rectangular planter, we can assist with a custom mould or patterns available in the Reckli Formliner catalogue: Reckli Formliner.

Contact our sales team to discuss your preferred pattern to determine suitability before specifying.

Timber options

We use native Australian hardwood, known as Spotted Gum, for all timber seating units (unless specified differently).

Spotted Gum produces a wavy grain and its striking appearance as well as its natural durability and strength makes it a popular choice for the architecture, interiors and construction industries. Spotted Gum is an Australian Standard bushfire-rated timber and is harvested from both commercial plantations and native forests in NSW and QLD.

Our timber is PEFC certified that it is sourced from sustainably managed forests, is manufactured to comply with AS 2082-2000, is fire rated to BAL 29 and Chain of Custody as per AS 4707.

All timber is primed with Teknos Aqua Primer Oak Stain and sealed with Intergrain Universal Timber Oil (unless specified differently).

Spotted Gum can be substituted with a timber and sealant of your choice, please contact us to discuss suitability before specifying and note that additional costs will apply.

Images show a variety of timber options.

Upholstery

Upholstered seating inserts can be added to our Deco, Pod, Alfresco and Bondi ranges where a timber alternative is required.

Upholstered inserts allow our bench seats, circular seats and seat planters to seamlessly transition from the exterior into the interior, or provides a more comfortable yet hard-wearing seating solution to the exterior landscape.

We collaborate with a leading furniture designer and manufacturer to create seating templates and inserts that seamlessly attach to our GRC bases.

Feet, Castor Wheels & Skate Deterrents

Feet Options for Planter boxes

Our square and rectangular planter boxes come standard with 10 mm high strip feet cast into the base.

Depending on size, most planter boxes can also be customised with 15, 40 or 65 mm high block feet if added height is required.

Our square and rectangular planter boxes come standard with 10 mm high strip feet cast into the base.

Depending on size, most planter boxes can also be customised with 15, 40 or 65 mm high block feet if added height is required.

Castor Wheels for Planter boxes

If planters need to be moved from time to time, we can fit castor wheels onto the planter base. Typically two of the four castors will have brakes built into them.

Not all planters and planter boxes are suitable for fitting castors, please contact our sales team to discuss your requirements.

If planters need to be moved from time to time, we can fit castor wheels onto the planter base. Typically two of the four castors will have brakes built into them.

Not all planters and planter boxes are suitable for fitting castors, please contact our sales team to discuss your requirements.

Skate Deterrents

Stainless steel anti-skate studs can be installed to deter skateboarders from marking planters and street furniture.

Stainless steel anti-skate studs can be installed to deter skateboarders from marking planters and street furniture.

Lifting & Fixing options

Ferrules

Some of our seating ranges come with ferrules already embedded in the base for permanent fixing and installation on site.

We are also able to embed ferrules in some of our other GRC product ranges on request to facilitate transport, movement and permanent installation on site.

Some of our seating ranges come with ferrules already embedded in the base for permanent fixing and installation on site.

We are also able to embed ferrules in some of our other GRC product ranges on request to facilitate transport, movement and permanent installation on site.

Lifting Lugs

We can insert lifting lugs into our products during manufacture and can also provide engineered certification to assist with crane lifting and placement on site.

Both options are available on request and we suggest discussing your requirements with our sales team.

We can insert lifting lugs into our products during manufacture and can also provide engineered certification to assist with crane lifting and placement on site.

Both options are available on request and we suggest discussing your requirements with our sales team.

Modifications

LED Strip Lights

We’re able to insert custom block outs into the base of some of our planter and seating ranges during manufacturing to create a recess for the installation of LED strip lights on site.

We’re able to insert custom block outs into the base of some of our planter and seating ranges during manufacturing to create a recess for the installation of LED strip lights on site.

GPO, USB Ports and Wireless Charging

We’re able to insert custom block outs into the base or sides of some of our planter and seating ranges during manufacturing to create a recess for the installation of GPO and USB ports as well as wireless charging stations on site.

Discuss the size and location with our sales team.

We’re able to insert custom block outs into the base or sides of some of our planter and seating ranges during manufacturing to create a recess for the installation of GPO and USB ports as well as wireless charging stations on site.

Discuss the size and location with our sales team.

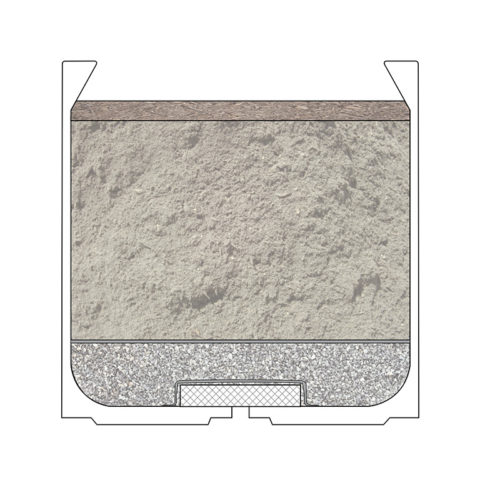

Waterproofing and Drainage

Our products come standard with clear Acrylic-based internal waterproofing and with drainage channels, holes and aids already installed. (Unless specified without). The location, size and number of drainage holes relate to the size of the planter and its soil volume.

For more information on our drainage aids, including a planting guide, please download our Drainage Guide.

WATERPROOFING

Quatro Design planters come standard with complimentary clear Acrylic-based internal waterproofing.

Black Bitumen-based internal waterproofing membrane can be added at an additional cost, and is best suited for use when products are converted into water features. A non-toxic and fish-safe waterproofing option is also available.

Quatro Design planters come standard with complimentary clear Acrylic-based internal waterproofing.

Black Bitumen-based internal waterproofing membrane can be added at an additional cost, and is best suited for use when products are converted into water features. A non-toxic and fish-safe waterproofing option is also available.

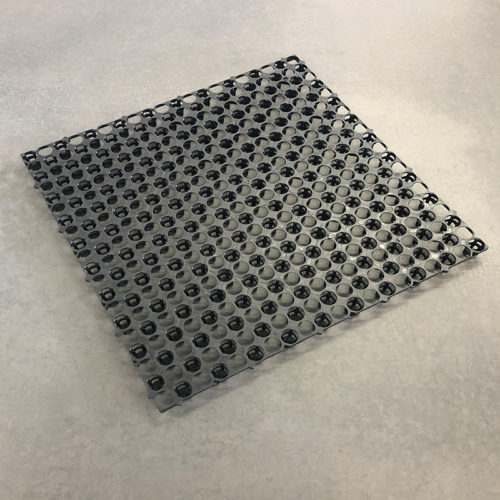

DRAINAGE CELL

VersiFlex flexible drainage cells are fitted to our large and over-sized pots and planters. These interlocking drainage cells are designed for use in planter boxes, roof gardens and retaining walls. Their open surface design and high internal void volume enable the rapid capture and transport of water volume to result in efficient drainage.

The Drainage Cells are covered by a thin layer of Geofabric filterwrap to prevent the drainage hole from blocking whilst still allowing water and fine particles to pass through.

VersiFlex flexible drainage cells are fitted to our large and over-sized pots and planters. These interlocking drainage cells are designed for use in planter boxes, roof gardens and retaining walls. Their open surface design and high internal void volume enable the rapid capture and transport of water volume to result in efficient drainage.

The Drainage Cells are covered by a thin layer of Geofabric filterwrap to prevent the drainage hole from blocking whilst still allowing water and fine particles to pass through.

DRAINAGE REGULATOR RISER

Drainage Regulator Risers are often installed when the amount of water draining from the base of the pot should be limited. They create an approximate 60 mm high water reservoir at the base of the pot to prevent excess water from draining away.

The Drainage Regulator Riser is covered by a thin layer of Geofabric filterwrap to prevent the drainage hole from blocking whilst still allowing water and fine particles to pass through.

Drainage Regulator Risers are often installed when the amount of water draining from the base of the pot should be limited. They create an approximate 60 mm high water reservoir at the base of the pot to prevent excess water from draining away.

The Drainage Regulator Riser is covered by a thin layer of Geofabric filterwrap to prevent the drainage hole from blocking whilst still allowing water and fine particles to pass through.

Custom Product Design & Manufacture

The creation of bespoke pieces is one of the most rewarding aspects of what we do. Glassfibre Reinforced Concrete’s (GRC) ability to be shaped and moulded into virtually any shape and size brings creative freedom and endless design possibilities to public space design.

We partner with you to collaboratively resolve your design vision and custom project and product concepts. Our design team work through your drawings and specifications and can provide guidance on the parameters of mould-making and manufacturing with GRC. They can also produce two or three dimensional drawings to help you envision the final product.

The specifications of some of our existing product ranges can also be modified to suit your project needs.

Visit our Custom Design and Manufacture page for more information and discuss your requirements with our sales team.