Custom Design & Manufacture

Public space and commercial projects often require the design and manufacture of bespoke custom planters and furniture to suit its design intent and occupancy requirements.

Quatro’s custom design and manufacturing experience combined with our collaborative relationship with the design industry turns any idea into a functional, yet aesthetically pleasing solution.

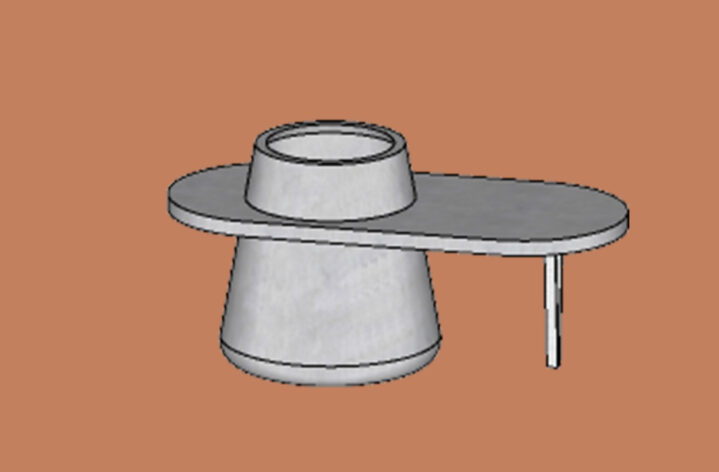

We have assisted the architecture, landscape architecture and interiors industry with numerous custom pots, planters, planter boxes, bench seats and large round seat planter solutions over the years and continue to work with Australia’s leading design firms to bring their vision to life.

Download our detailed Custom Design and Manufacturing guide here

Custom Design & Manufacture Process

It all starts with an idea and our experienced team can assist you with your custom product concepts from initial enquiry right through to product delivery.

Step One

Concept Design

Our experienced team provides guidance on design implementation, GRC suitability, mould making considerations and most importantly can suggest cost saving solutions based on your concept designs. Indicative costs are also provided.

Step two

Detailed Design

Detailed quotations and custom product design drawings are prepared based on the outcomes from the conceptual design stage. Once approved we’ll prepare shop drawings for your final sign-off and records.

Step three

Mould Making

Our experienced team of mould makers create an exact replica of the product (known as a plug), this will be used as a template from which to create the mould. Plugs are commonly created using CNC routing and cutting techniques and can be made from foam or timber.

Timber or Fibreglass resin and expert craftsmanship is combined to create a reverse image (a mould) of the product. The mould undergoes a final quality check to ensure that it has a flawless and smooth surface and is ready to go into production.

Step four

GRC Production

Our GRC mixture is sprayed into the mould and layered until the desired product wall thickness is achieved. The newly moulded product is left to cure overnight and once de-moulded is sent though to our detailing department where it’s inspected to ensure that each individual component meets our stringent quality standards.

Step five

Delivery

In collaboration with your site contact we make delivery arrangements to suit your unique installations requirements. The custom products are packaged and wrapped to ensure that they reach you in perfect condition, and we use reputable freight carriers with whom we’ve built strong relationships over the years to get them to you on time.

Custom Engineered Certification & Solutions

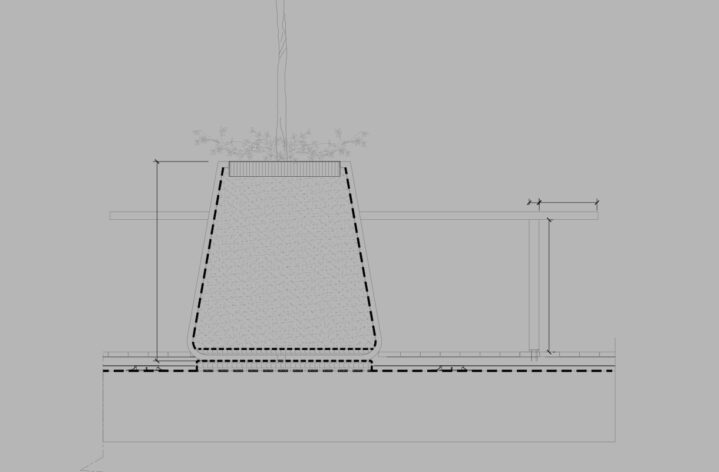

Some projects and installations require certification and sign-off by an engineer, for example when planter boxes are used as balustrades or attached to the building’s façade. We successfully partner with your or our own engineering consultant to ensure that all products and their components are certified and comply with all required safety and installations standards.

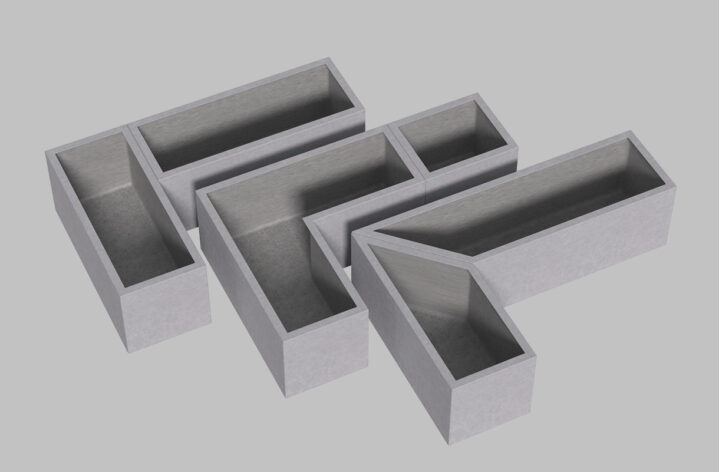

Custom Planter Boxes

We can custom make trough planter boxes to nearly any size and height to suit your project requirements, whether they are balustrade or balcony planters, nested planter boxes or if additional length or height is needed to suit a challenging space.

We work collaboratively with you to resolve the custom planter box design and consider your lifting, irrigation, drainage and installation requirements during the initial quoting and design stage to ensure that the planter boxes are custom manufactured to perfectly suit your project and budget.

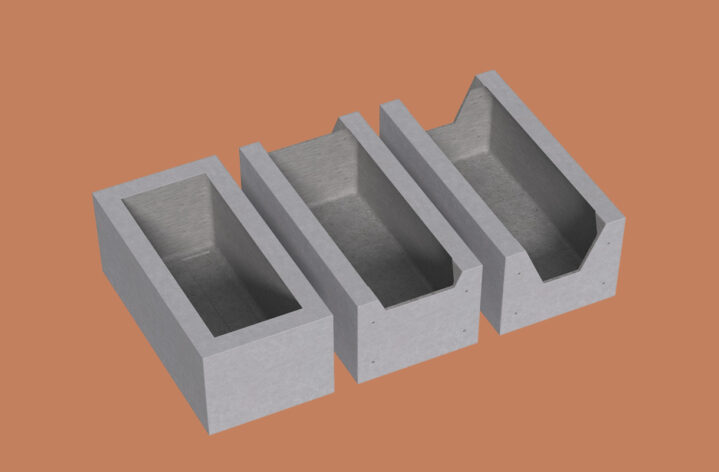

Planter Box Modifications

Planter Walls

One or more of our planter box walls can be lowered to create the illusion of one continues planter once installed, or to create interest and screening with varying planter wall heights.

Rounded Edges

Some of our square and through planter boxes can be modified to include rounded or tapered edges if a less angular look is required for the landscape.

Alternative Corners

Our planter boxes can be custom manufactured to suit a variety of corner configurations on site, for example L-joints or mitred corners.